Rubber Bearing Pads

Product Details:

- Water Absorption Low

- Usage & Applications Bridge construction, Building support, Vibration isolation

- Thermal Conductivity 0.13 W/mK

- Feature Anti-vibration, Load bearing, Weather resistant

- Style Rectangular or square

- Tensile Strength Above 15 MPa

- Size Custom as per requirement

- Click to view more

Rubber Bearing Pads Price And Quantity

- 100 Meter

- 100 INR/Meter

Rubber Bearing Pads Product Specifications

- Above 15 MPa

- Rectangular or square

- Custom as per requirement

- 0.13 W/mK

- Anti-vibration, Load bearing, Weather resistant

- Bridge construction, Building support, Vibration isolation

- Low

- Less than 1%

- Available

- Below 2%

- 100 mm to 600 mm

- Natural rubber, synthetic rubber

- 1.20 Gram per cubic centimeter(g/cm3)

- Smooth

- 2 mm

- 10 mm to 100 mm

- Natural, Neoprene

- Depends on dimensions

- Reinforced rubber layers, steel plates (optional)

- 8% to 15%

- Standard rubber flame resistance

- Bearing pad

- High against weather, water and chemicals

- Negligible

- 60-70 Shore A

- -20C to +80C

- Black

- Not applicable for square pad

- Rubber Bearing Pad

- 100 mm to 600 mm

Rubber Bearing Pads Trade Information

- 1000 Meter Per Day

- 3 - 4 Week

- Yes

- Free samples are available

- Australia, Eastern Europe, Middle East, Western Europe, South America, Asia, Central America, North America, Africa

- All India

Product Description

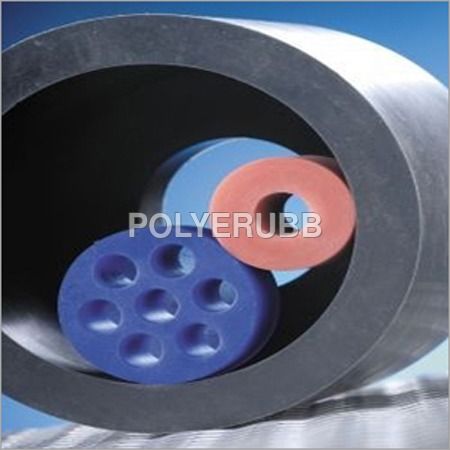

Rubber Bearing Pad is a heavy duty element which is made of synthetic elastomeric rubber like neoprene which exhibits an excellent chemical stability and is highly flexible over a wide range of temperatures. It is widely used in the building and bridge construction that can be placed in between superstructures like the bridge beam and elements such as the vertical supports called piers. The main function of the Rubber Bearing Pads is to distribute the extreme loads of large structural bodies and allows the necessary movement without creating harmful stresses that may lead to compromise in structural integrity.

Product details

|

Size |

Up to 300 mm |

|

Brand |

Polyerubb |

|

Shape |

Square |

|

Hardness |

30-90 A |

|

Tensile Strength |

100-300 Mpa |

|

Density |

1.0-2.0g/cm3 |

|

Temperature |

200 Degree C |

|

Tolerance |

+/-0.05 mm |

|

Material |

Rubber |

|

Color |

Black |

Exceptional Performance and Flexibility

Our Rubber Bearing Pads are crafted to withstand high load capacities while maintaining outstanding flexibility and elongation, with a break threshold above 450%. The pads recover more than 95% after compression, ensuring long-term effectiveness in energy dissipation and shock absorption. This makes them ideal for critical structural support, where consistent performance is vital.

Versatile Applications in Construction and Engineering

Designed for direct installation between structural components, these bearing pads are perfect for uses from bridge construction to building supports and vibration isolation. Their weather and chemical resistance, along with minimal maintenance requirements, allow them to function reliably in both indoor and outdoor settings, providing adaptable solutions to diverse engineering challenges.

Customizable Designs for Project Needs

Offering a wide range of sizes and shapes, the bearing pads can be tailor-made to exact specificationswhether rectangular or square, plain or patterned texture, and available with or without steel laminates. This customization, along with precise tolerances and a choice of rubber type, ensures that each application receives the optimized pad for its requirements.

FAQs of Rubber Bearing Pads:

Q: How are Rubber Bearing Pads installed in structural applications?

A: Rubber Bearing Pads are installed through direct placement between structural elements, such as beams and foundations. Their design allows for simple and efficient installation without the need for adhesive or mechanical fasteners, streamlining the process during construction.Q: What benefits do these bearing pads offer in terms of durability and longevity?

A: With a service life exceeding 15 years and a recovery rate after compression above 95%, these pads provide long-term, reliable support. Manufactured with high-quality natural and synthetic rubber, they resist weather, water, and chemical damage, ensuring sustained performance over their shelf and service life.Q: Where can Rubber Bearing Pads be effectively utilized?

A: These pads are ideally suited for bridge construction, building supports, and vibration isolation systems. Their flexibility and robust physical properties enable use in both indoor and outdoor environments, making them a versatile choice for diverse engineering needs.Q: What maintenance is required for Rubber Bearing Pads during their service life?

A: Rubber Bearing Pads require minimal maintenance due to their excellent resistance to weather, water, and chemicals. Routine visual inspections are suggested to ensure integrity but generally, their robust construction reduces the need for frequent attention.Q: When is it necessary to replace these pads?

A: Replacement is typically needed only after the service life of more than 15 years or if physical damage or permanent deformation is observed. However, adhering to the specified shelf life of 5 years before installation ensures optimal performance.Q: What customization options are available for these bearing pads?

A: Pads can be customized in width (100600 mm), length (100600 mm), thickness (10100 mm), surface texture (plain or patterned), material (natural or neoprene rubber), and with or without steel laminates. This allows adaptation to specific load, size, and environmental requirements.Q: How should Rubber Bearing Pads be stored before installation?

A: Store the pads in a dry, cool place away from direct sunlight to preserve their quality. They are typically packaged on wooden pallets or as per customer requirements to prevent any physical damage during storage or transit.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+