Dam Gate Rubber Seals

300.00 INR/Meter

Product Details:

- Natural Rubber Yes

- Hardness 40-60 Shore A

- Usage & Applications Industrial

- Resistance level High

- Color White

- Material Rubber

- Click to view more

X

Dam Gate Rubber Seals Price And Quantity

- 300.00 INR/Meter

- 100 Meter

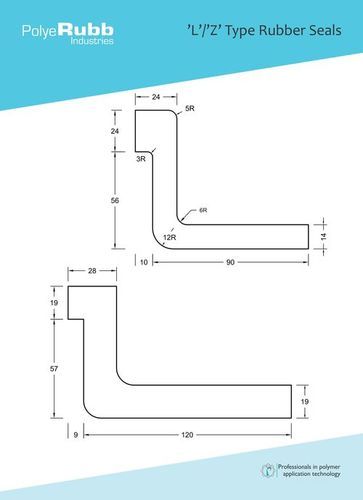

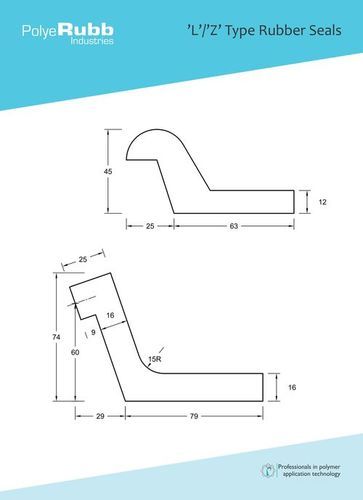

Dam Gate Rubber Seals Product Specifications

- 40-60 Shore A

- Yes

- High

- Industrial

- Rubber

- White

Dam Gate Rubber Seals Trade Information

- 100 Meter Per Day

- 3 Days

Product Description

These Dam Gate Rubber Seals are manufactured under the stern vigilance of sincere professionals with the aid of modern molding techniques. The provided seals are widely demanded to be installed with dam gates for prevention of leakage of fast flowing water. The offered Dam Gate Rubber Seals are known for their sturdiness, easy installation, dimensional accuracy, high strength and perfect finish.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free